Blog

Castings defects in China Foundry

Castings defects are the general name of various defects produced on the surface and inside of casting parts, castings defects also are the important reasons for the low performance, short service life and failure of castings. In order to prevent, reduce and even eliminate casting defects,Foundry needs to analyze casting defects,causes and forming process during casting.Of course,It's not a simple work for some foundry in China,It also requires sufficient technical strength and experience to solve some problem when actual production.However fortunately,Dandong Iron Casting Group is good producers for castings.Castings quality mainly includes appearance quality, internal quality and use quality,as follows:

Appearance quality refers to surface roughness, surface defects, dimensional deviation, shape deviation, weight deviation of castings.Internal quality mainly refers to the chemical composition, physical properties, mechanical properties, metallographic structure of castings,as well as holes, cracks, inclusions, segregation etc.

Castings use quality refers to the working durability under different conditions, including wear resistance, corrosion resistance, heat resistance, fatigue, shock absorption and other properties.

The castings quality has a great influence on the mechanical properties,For example, the wear resistance and dimensional stability of machine tool castings,directly affect the precision maintenance and service life of machine tools.However,many factors affect castings quality,Including castings design process, reasonable and correct casting process, castings raw materials quality and correct operation process.

In casting production, Dandong Iron Casting Group will control and inspect the casting quality.First we have strict control from Raw material to Auxiliary Material,our foundry buys pig iron from large state-owned steel mills and stored in designated raw material storage area.

Each casting process is controlled and inspected in strict accordance with process codes and technical conditions.Finally, our quality team makes quality inspection of finished castings,Liaoning Tengfei factory owns three coordinate detector, X ray inspection machine and ultrasonic detector etc.

Sand castings defects include: air hole ,shrinkage porosity, sand holes,casting scar,Sand inclusion,wrong shape,cold insulation, Cold insulation, trimming,welding hot breaking,cold cracks and so on.

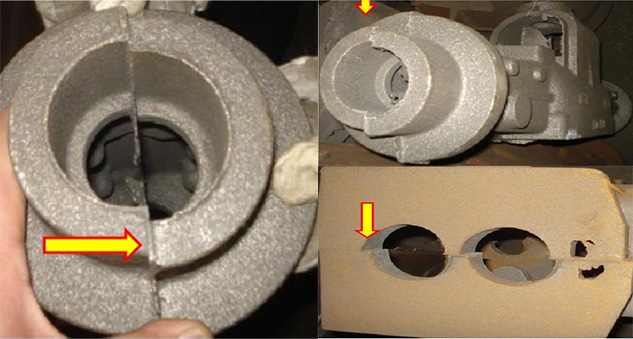

Air hole

Air hole also known as air eyes,which is one of the most common defects in casting production.It is mainly produced on the inside, surface or near surface of the casting, and is round, long and irregular in different sizes.The main causes of air hole are related to casting process, casting alloy materials, alloy melting and other factors.Therefore, our foundry needs to judge the castings defects according to the air hole location, characteristics, adopted process and molding sand for comprehensive analysis, and then take corresponding technical measures to prevent and eliminate defects.

Shrinkage porosity

Shrinkage refers to the area where the casting is finally solidified without the replacement of liquid metal or alloy to form dispersed and fine shrinkage holes.Mainly distributed in the casting parts wall thickness area, riser and internal gate position.

Shrinkage holes are mainly distributed on the outer surface of casting parts, which can be simply viewed by the naked eye.However,Shrinkage is hidden inside the casting, it is not easy to find in appearance.Our foundry often use X ray inspection machine to judge shrinkage defect.

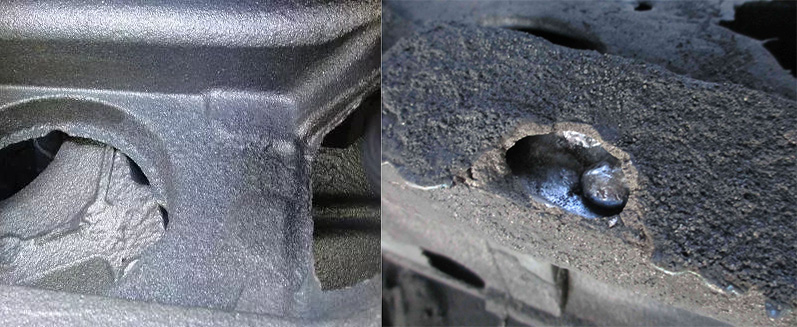

Casting scar

Casting scar refers to the rough surface and raised of the casting,the main reason is the evaporation of residual moisture in molding sand.Quality inspectors need to use X-ray to to determine whether has the casting scar.

Sand inclusion

The surface of the casting produces scarlike metal protrusions with rough surfaces and sharp edges,It's called Sand inclusion. Sand inclusion belongs surface defect,mainly produced on the outer surface of the casting.It not only affects the appearance quality of castings,but also affects the service life of castings.

Foundry needs to solve these problems as soon as possible when they happen,adjust production process,use fine grain size of casting sand and increase mold permeability.

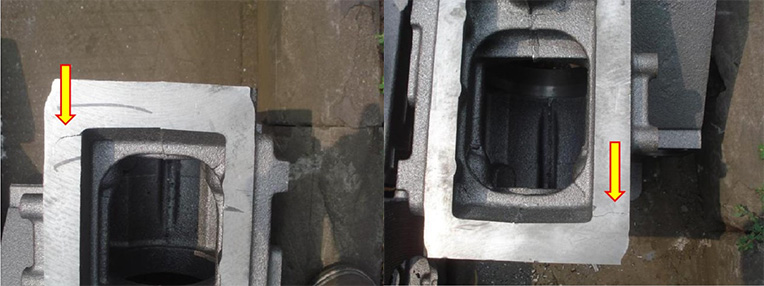

Wrong shape

The wrong shape is also called the wrong side,which is one of the common casting defects.It is due to the asymmetry between the upper box and the lower box when closing the box.

Prevention methods:Fixed sandbox and corrected plate.

Cold insulation

The cold insulation is caused by the low pouring temperature of metal liquid and poor fluidity,also includes the unreasonable design of the gating system and the obstruction of the flow of metal liquid in the cavity.it occurs mostly on the surface and thin wall of the casting,which seriously reduce the mechanical properties and service life of castings. Methods to prevent underpouring and cold isolation: increasing pouring temperature and pouring speed.

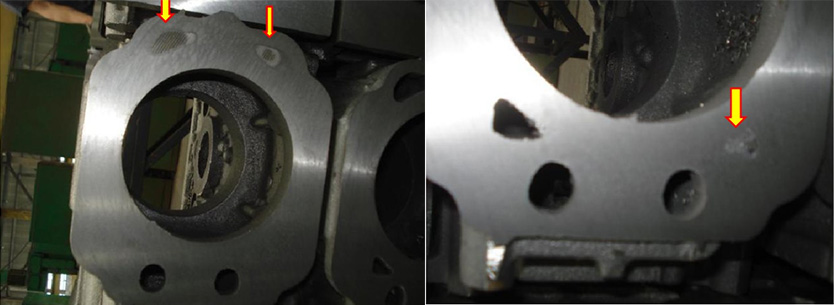

Cooling crack

In the low temperature environment, the cracks formed when the internal stress of the casting exceeds the strength limit of the alloy are called cold cracks. Cold cracking is also a serious defect in castings,which will affect appearance quality and internal mechanical properties.

Cold cracking often occurs in the parts where the casting is stretched, especially the parts with stress concentration and the parts with casting defects.Cold crack and hot crack of casting are produced by the action of stress, only the time of crack production is different.

Measures to Prevent Cold Cracks:

1. Improving uniformity of casting structure and wall thickness.

2. Reasonable setting of pouring system,avoid casting line shrinkage obstruction and Reducing Cast Stress.

3. Control of C、Cr、Mn、P content in molten steel.